Our manufacturing capacity can be increased in high-demand periods and reduced during low periods. The ability to adapt means our prices are always competitive and we have the production times to match.

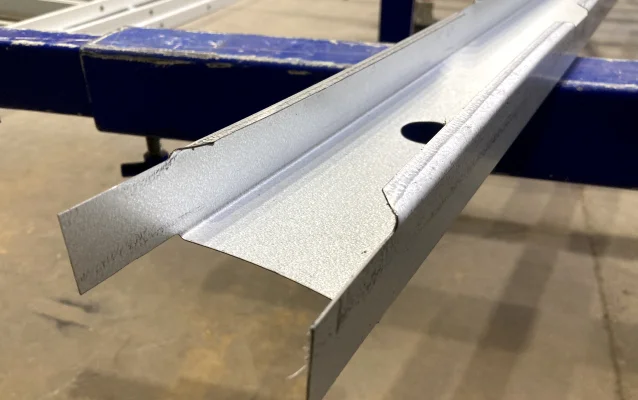

Every frame, truss, floor joist, and facade undergoes a strict quality assurance process before leaving the factory.

Our large facility in South Albury means we can store projects, so they are ready for collection or delivery. We can organise delivery with our own staff or delivery contractors.

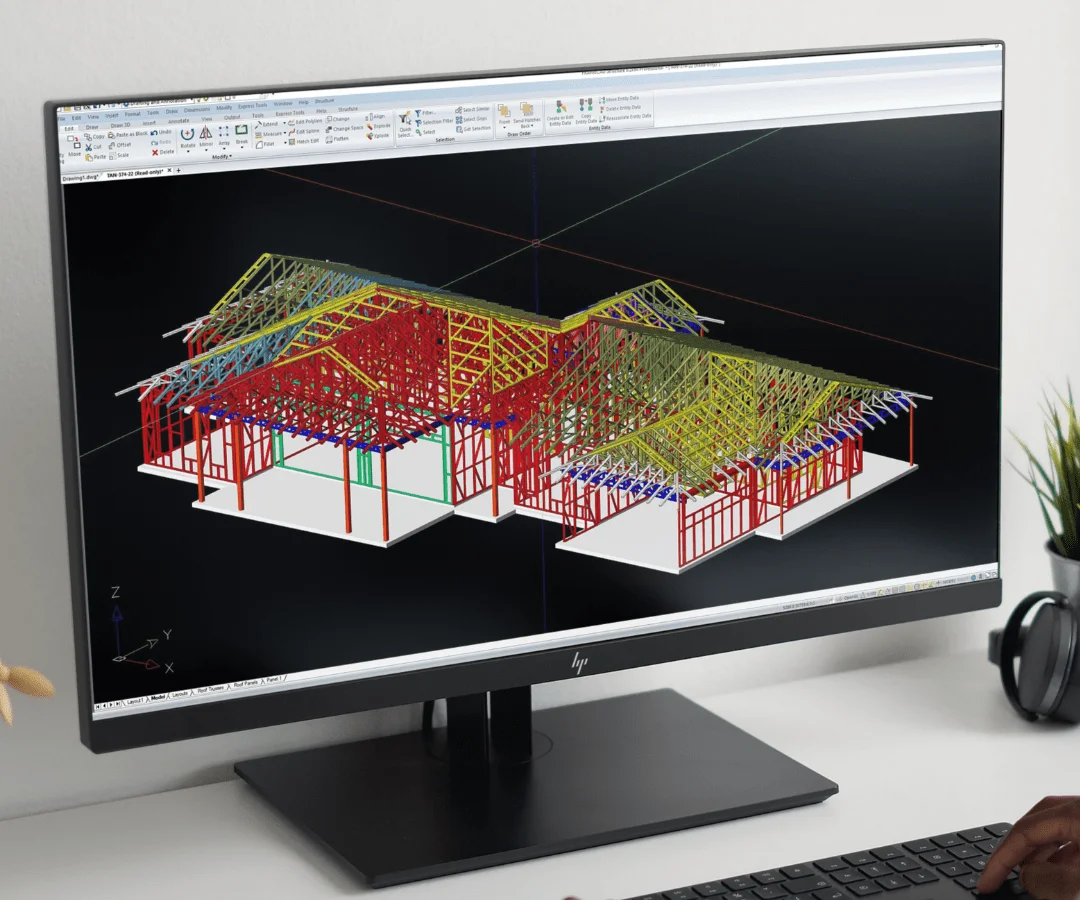

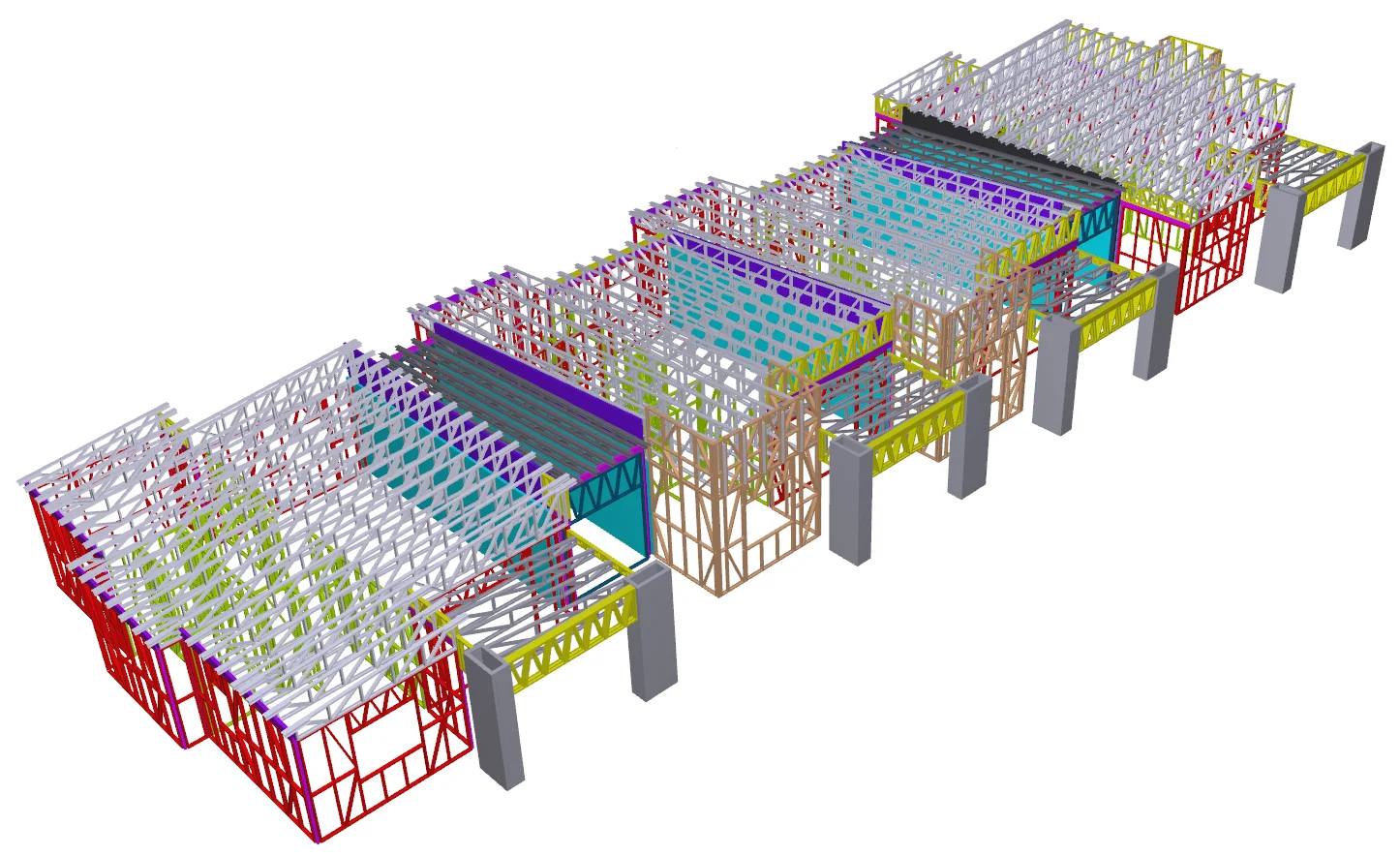

On supply-only jobs, we provide in-depth plans and shop drawings to match the labelling on the frames. They are easy to understand and make installation a breeze.

Our quick manufacturing will ensure you have your frames when you need them. Any alteration that needs to be made will also be onsite as quickly as possible.

We will supply a detailed set of plans and shop drawings. The frames will also be clearly labelled ensuring no confusion during the installation.

We understand programs often change. We have significant space to store your project until you are ready for it.

Our lightweight frame makes them easy to manoeuvre around the site, which makes them less of a safety risk than timber frames.

Your account manager will work with you on the timing and order of delivery. This can be a significant help when there is limited space on the job site.

It’s important the scope of the project is determined for clarity between us and the client. And so we can provide accurate pricing.

Our team will begin designing the project once the scope and contract are agreed upon. We maintain communication to ensure the design fully satisfies your project requirements.

Once the design is complete our team will send a copy to the client, highlighting any areas requiring attention. This is an important part of the process to ensure clarity across all parties.

Now the project is ready to go into production. Your account manager will communicate when your project is complete.

Our team will ensure your project arrives on time and in the order of installation. When unloading, the driver will try to leave the frames as close to the project as possible.

Yes, Nurigong Steel has a rolled forming machine to cold-form light gauge steel into studs and tracks. Then the studs are prefabricated in our factory before delivery.

Yes, it is the design that is structurally certified.

It depends on the size of the job and the distance from our factory.

No, this is not necessary for LGS trusses. The light weight of the truss and the inline design make them easy to pass up to rooves of single-story houses.

Copyright © 2024 Nurigong Steel – All Rights Reserved

Nurigong Steel acknowledges the Traditional Custodians of the many Countries throughout Australia and their connections to land, sea and community. We acknowledge the contributions and sophistication of Aboriginal and/or Torres Strait Islander knowledge and culture.

Nurigong Steel acknowledges the Traditional Custodians of the many Countries throughout Australia and their connections to land, sea and community. We acknowledge the contributions and sophistication of Aboriginal and/or Torres Strait Islander knowledge and culture.