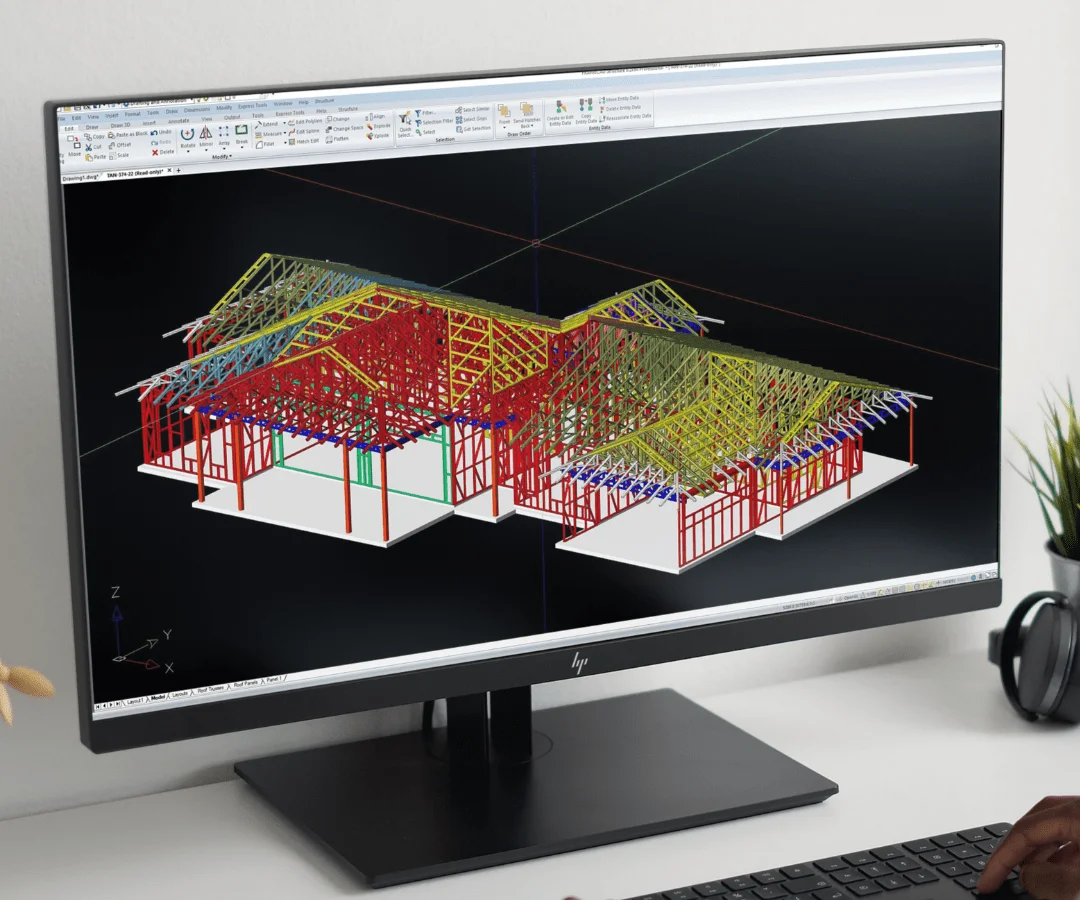

Our in-house detailing team will design and detail the project before sending it to manufacturing. Having the team on hand allows us to make changes to the design as required throughout the entire project.

When possible we utilise onsite measures before manufacturing frames. This is particularly beneficial to ensure the installation goes smoothly.

When required we will provide architectural steel design structural certifications.

Design, manufacture, and installation will comply with AS/NZS 4600 and the NASH Standard.

Onsite measures are critical to the overall speed of installation. Ensuring everything fits before starting the installation makes for a quick and smooth process onsite.

Our thorough process allows us to find cost savings through smart designs.

Quality of finish is our highest priority. Getting us involved in the process early will allow us to use our expertise to help you produce the highest quality results.

We take pride in working cohesively with other trades, not only on site but also in design.

Combining with our associate company, Tru Services Group, we can package the framing and plastering to ensure the two products are completed by one team.

Our project managers will deep dive into the project requirements from tender past contract letting. During the tender process, we can suggest suitable cost savings.

Shop drawings are not provided during the tender phase, however we can provide examples of completed projects.

We will begin the detailing process once we have agreed on a contract and a scope of work. We will maintain contact with the builder to ensure no surprises on site.

We will begin the detailing process once we have agreed on a contract and a scope of work. We will maintain contact with the builder to ensure no surprises on site.

On architecturally designed projects we will require the .DWG files.

Once the design is complete our team will send a copy to the builder, highlighting any areas requiring attention. This is an important part of the process to ensure clarity across all parties.

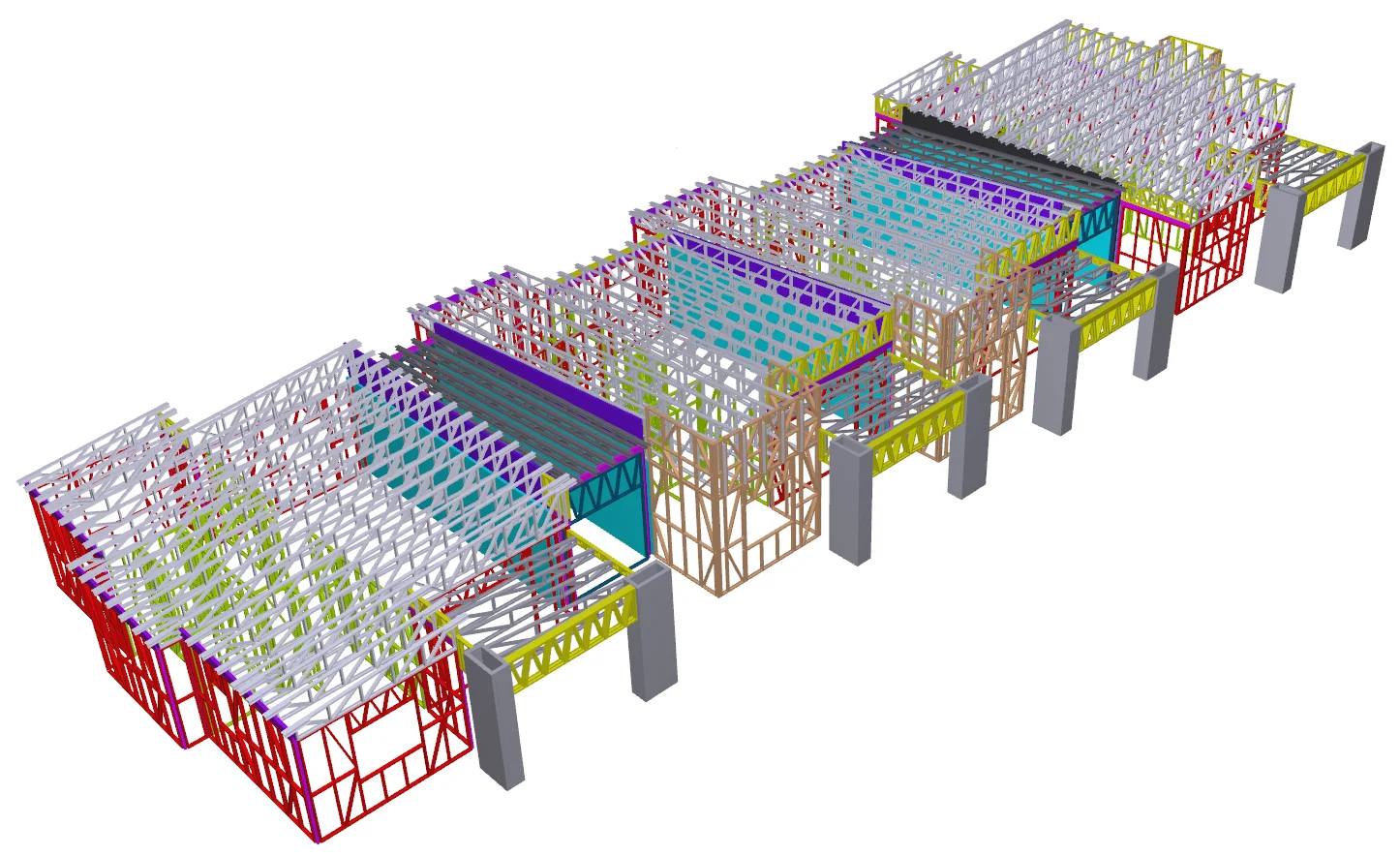

When we can, we prefer to complete an onsite measure before sending the job to manufacturing. This is another procedure to put in place risk mitigations and ensure onsite installation runs smoothly. We can also integrate the structural steel design into ours to mitigate risk.

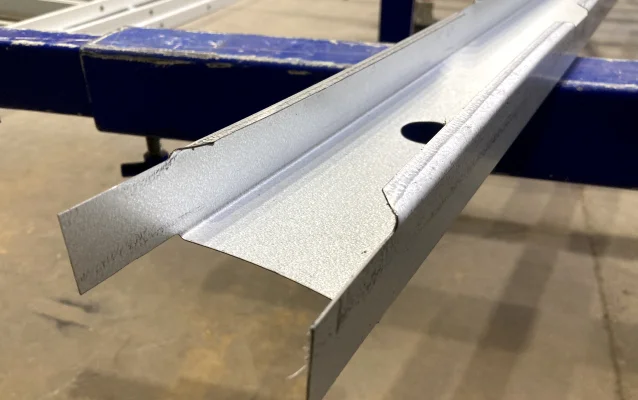

We have a large manufacturing facility based in Albury, NSW, where we prefabricate the frames. Once the frames are built they go through a quality assurance process before being stored in our yard. Having a large storage yard means we can prepare your frames ahead of time, ready for installation.

We have a large and qualified installation team of carpenters, plasterers and labourers. A project lead will be assigned the job with their crew. Pre-install meetings are completed and delivery is coordinated.

Variations are inevitable in construction. We stay ready to answer builders’ calls to troubleshoot where required.

We will need the construction drawings, the window and door opening sizes and the wind loading for the area. It also helps if we can get the structural steel’s 3D model to merge with ours.

We can supply structural certification of the designs.

It depends on the size of the project, our current backlog and how quick you can get us the required information. Get in contact so we can start planning the progress of your project.

Our products are light and strong making them more versatile than timber. We also have the ability to increase gauge or add bracing. With this in mind, our process is to work backwards by understanding the project requirements first and then designing products to meet them. Our software can incorporate hot-rolled steel if it becomes practical in certain situations.

Our designs comply with Australian Standards and the NASH standards. Our products can be used in buildings requiring fire, acoustic and thermal ratings. Contact our project managers to discuss more.

Copyright © 2024 Nurigong Steel – All Rights Reserved

Nurigong Steel acknowledges the Traditional Custodians of the many Countries throughout Australia and their connections to land, sea and community. We acknowledge the contributions and sophistication of Aboriginal and/or Torres Strait Islander knowledge and culture.

Nurigong Steel acknowledges the Traditional Custodians of the many Countries throughout Australia and their connections to land, sea and community. We acknowledge the contributions and sophistication of Aboriginal and/or Torres Strait Islander knowledge and culture.