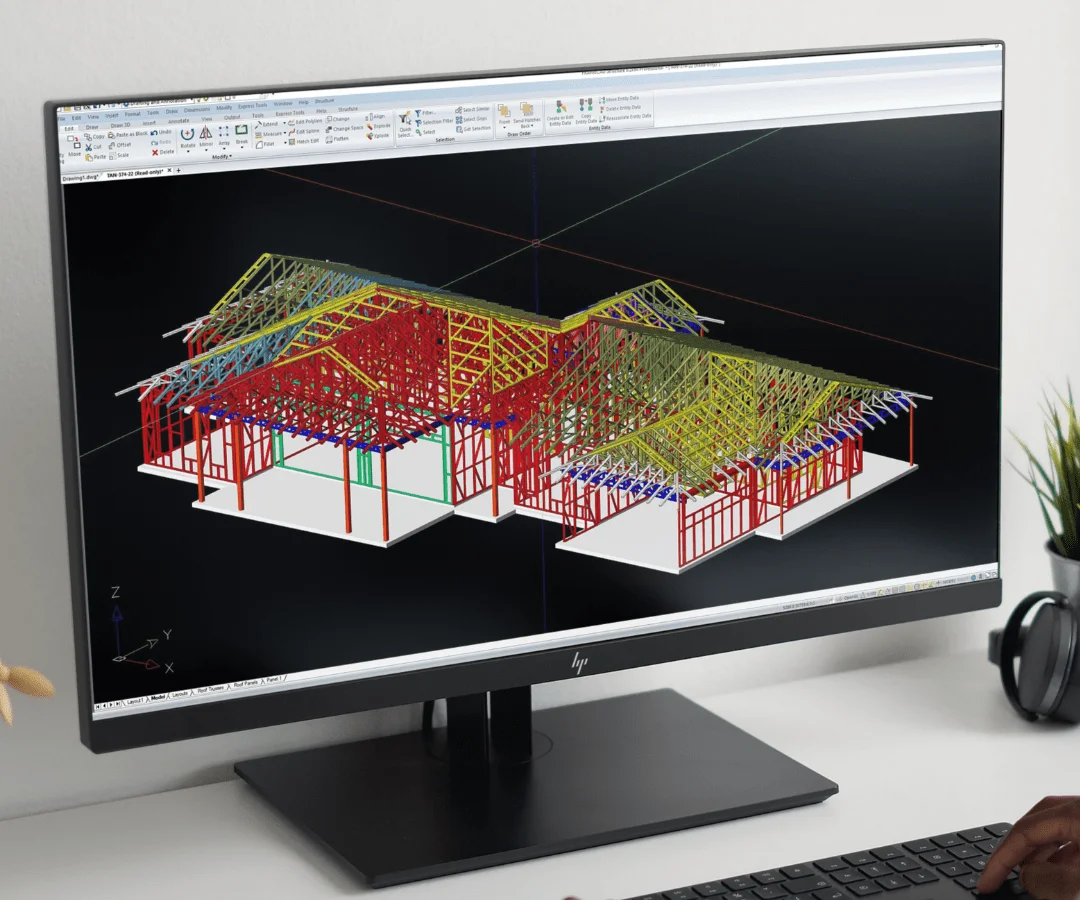

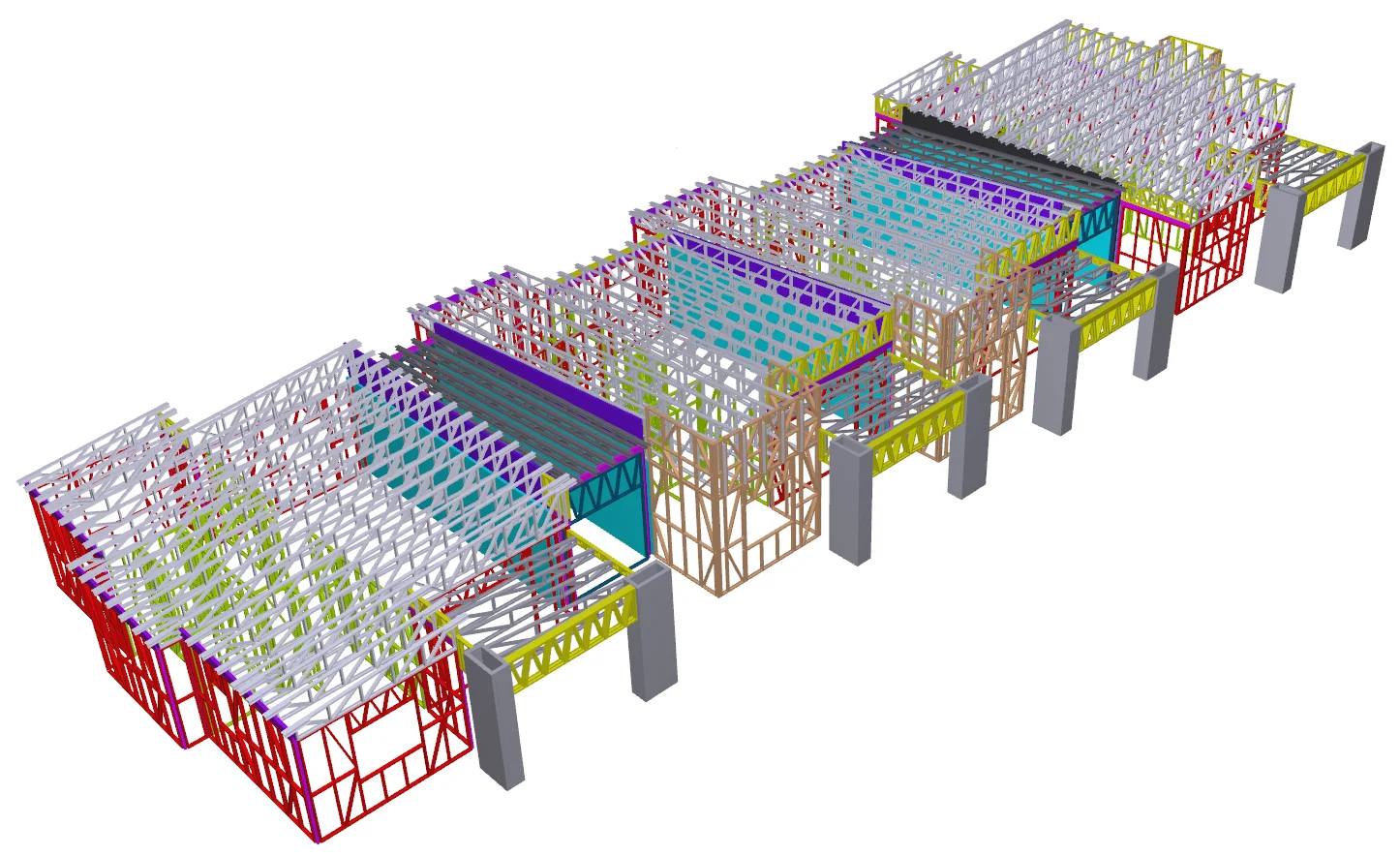

We offer design, manufacturing, delivery and install

The installation team is experienced with installation on projects that integrate the light gauge steel with structural steel, concrete tilt-up panels and more. Members also have elevated work platform tickets for installing at heights.

Our operational procedures for our design, manufacture, and installation projects ensure the install team clearly understands the project.

Our install team is constantly overcoming onsite challenges. To develop solutions they have the design and manufacturing team on their side. In most cases, the office and factory team can be working on a resolution while the install team focus their efforts elsewhere.

The install team has a meeting with the internal project manager to discuss the project details and review plans. This is also a chance to coordinate delivery.

We will coordinate the delivery to the site so the install team can hit the ground running.

Our team will be onsite to install in line with the project program.

After installation, a workthrough with the builder is completed for review and QA

Our installation team is made up of qualified carpenters, qualified plasterers and labourers.

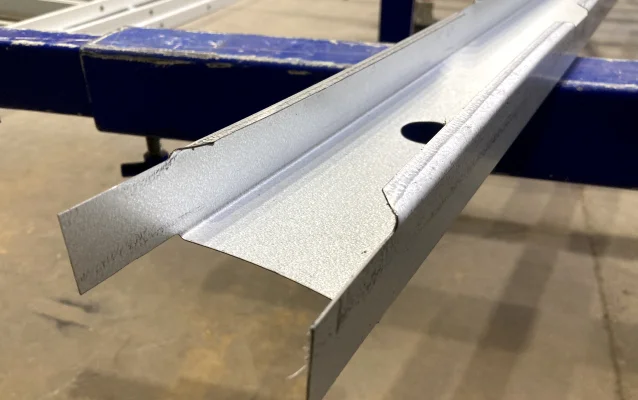

We manufacture an 89mm stud. However, we can also use other widths from suppliers of stick framing. This is less ideal but in some cases necessary.

We use a combination of both full-time employees and on some projects subcontractors.

Copyright © 2024 Nurigong Steel – All Rights Reserved

Nurigong Steel acknowledges the Traditional Custodians of the many Countries throughout Australia and their connections to land, sea and community. We acknowledge the contributions and sophistication of Aboriginal and/or Torres Strait Islander knowledge and culture.

Nurigong Steel acknowledges the Traditional Custodians of the many Countries throughout Australia and their connections to land, sea and community. We acknowledge the contributions and sophistication of Aboriginal and/or Torres Strait Islander knowledge and culture.