The manufacturing process starts by sourcing wholesale coils of light gauge steel to our factory in South Albury. We use reputable supply companies and only purchase the highest quality light gauge steel.

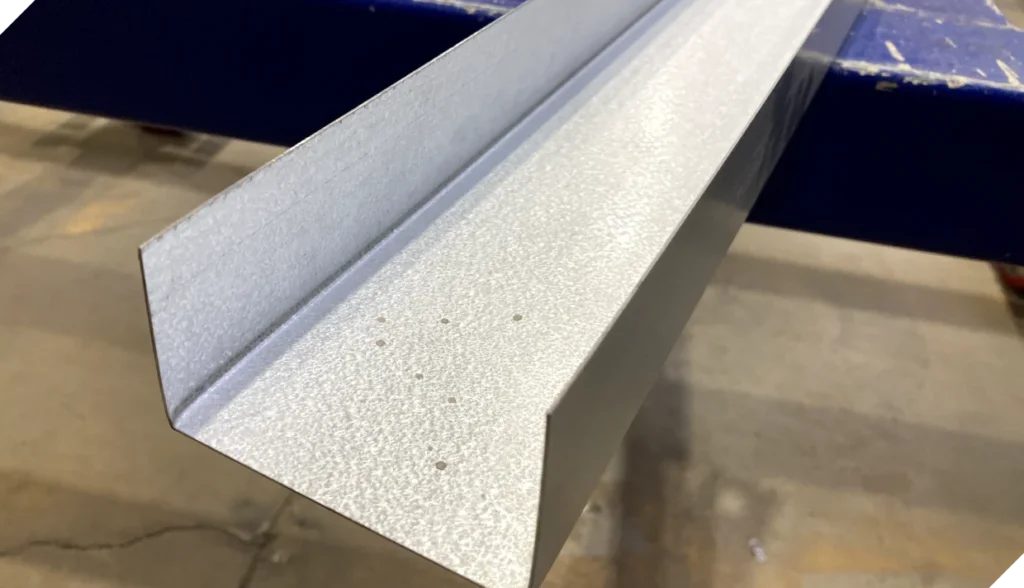

We cold form the steel into a c-section shape, to make studs specific to the design. This process cuts the coil to length and does not create much waste.

We then assemble the frames, trusses and joists at the factory for delivery.

Our machine has a tolerance of +/-0.05mm.

Unlike timber, steel frames are always straight.

Our LGS studs are just as strong as timber and are much lighter, making for more versatile designs.

Our studs are pre-pressed with a dimple hole for the screws. This creates a flat finish to install the covering.

The decreased weight means carrying frames is less. demanding on installers and the accuracy makes it right the first time

When we know alterations will need to be made onsite we use an unlipped U section for the top and bottom tracks. This allows installers to place studs with swaged ends at any location in the channel.

Ability to easily make changes onsite.

Same strength and profile as a normal stud wall.

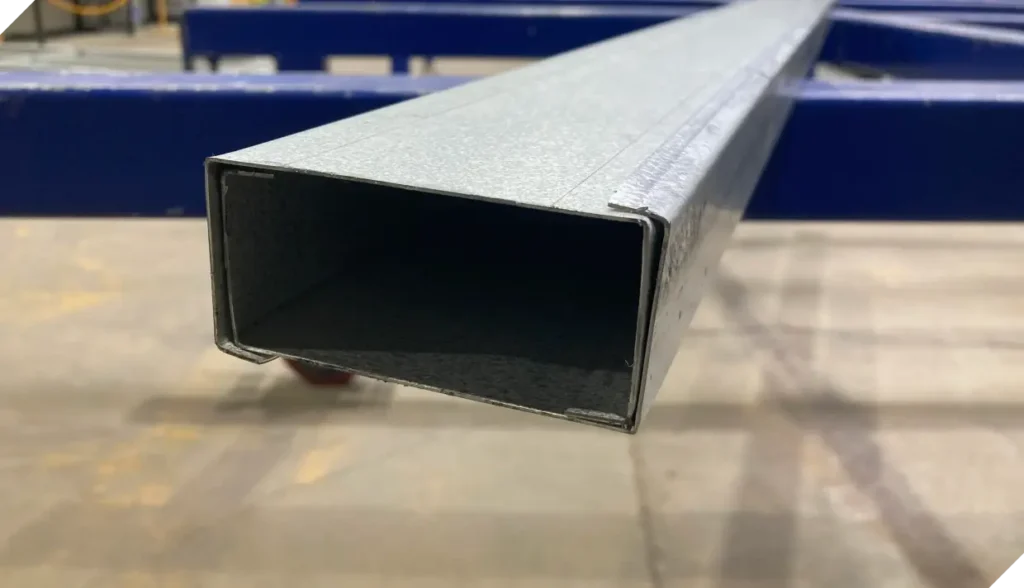

To increase strength of a design we can box studs. Boxed studs are two standard studs profiles combined to make a box profile, producing double the strength.

Double the strength.

Maintains the same width, so it can be incorporated with non-boxed stud walls, trusses etc.

Copyright © 2024 Nurigong Steel – All Rights Reserved

Nurigong Steel acknowledges the Traditional Custodians of the many Countries throughout Australia and their connections to land, sea and community. We acknowledge the contributions and sophistication of Aboriginal and/or Torres Strait Islander knowledge and culture.

Nurigong Steel acknowledges the Traditional Custodians of the many Countries throughout Australia and their connections to land, sea and community. We acknowledge the contributions and sophistication of Aboriginal and/or Torres Strait Islander knowledge and culture.