“Nurigong Steel are great to deal with and their product is high quality.”

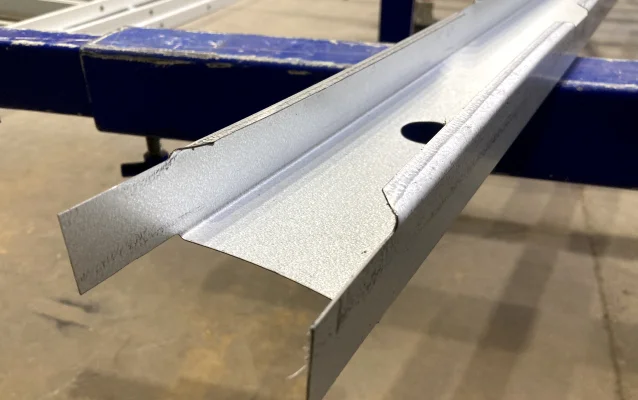

“I have been impressed with the prefabricated steel framing. It saves time, it’s cost relevant to timber and is very straight for plaster linings.”

“Nurigong Steel are great to deal with and their product is high quality.”

“I have been impressed with the prefabricated steel framing. It saves time, it’s cost relevant to timber and is very straight for plaster linings.”

Compared to timber, steel is more versatile, lighter making it easier to install, it's always straight, competitively priced, it produces less waste to make, and its termite proof.

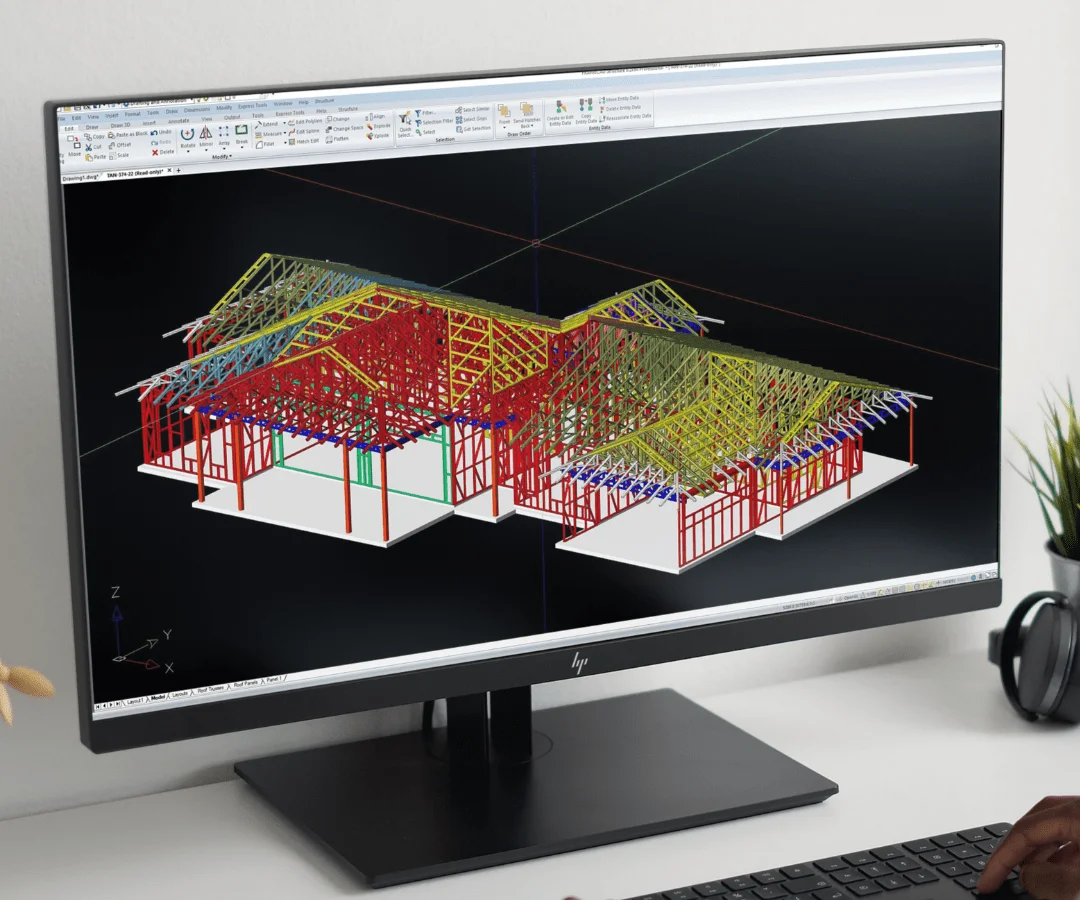

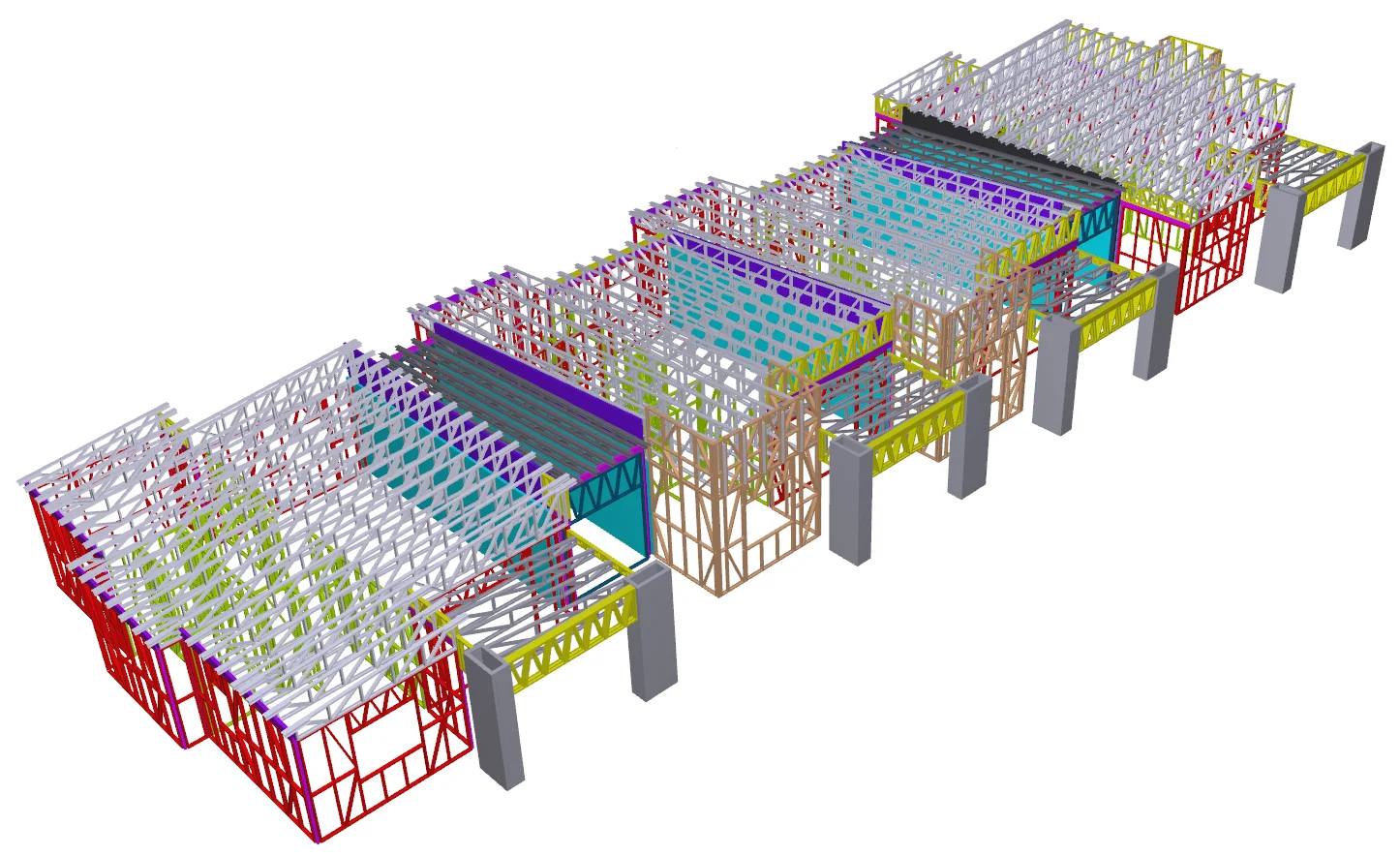

We have no issue in designing a party wall to meet the spec.

We have the ability to turn around jobs very quickly. However, for a typical job allow 2 weeks for detailing and another week for manufacturing and delivery.

Due to the increased efficiencies in manufacturing, we can supply a very competitive price compared to timber.

Copyright © 2024 Nurigong Steel – All Rights Reserved

Nurigong Steel acknowledges the Traditional Custodians of the many Countries throughout Australia and their connections to land, sea and community. We acknowledge the contributions and sophistication of Aboriginal and/or Torres Strait Islander knowledge and culture.

Nurigong Steel acknowledges the Traditional Custodians of the many Countries throughout Australia and their connections to land, sea and community. We acknowledge the contributions and sophistication of Aboriginal and/or Torres Strait Islander knowledge and culture.